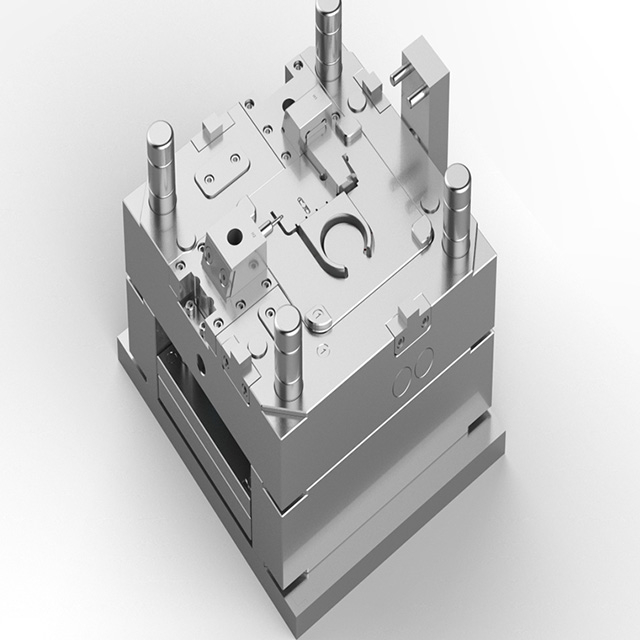

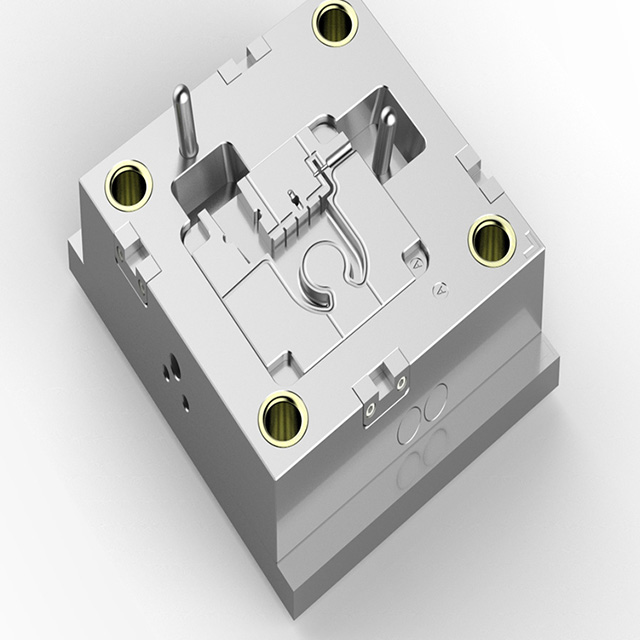

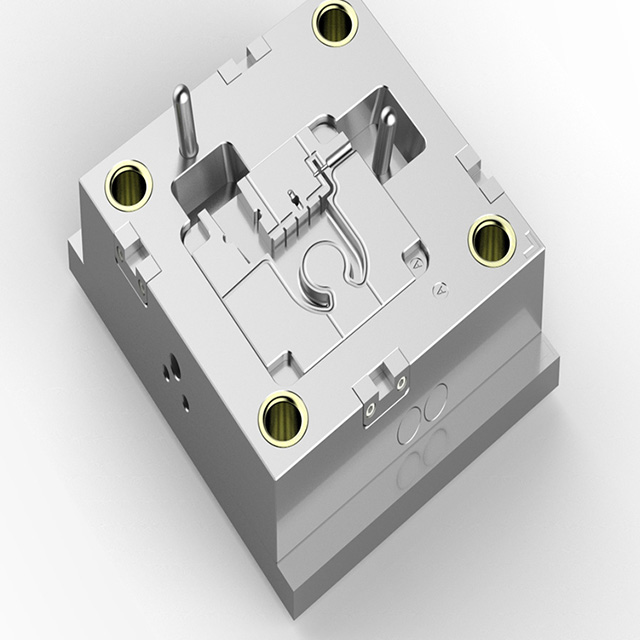

1.Part name: Injection tooling made by made by Shunho plastic solutions

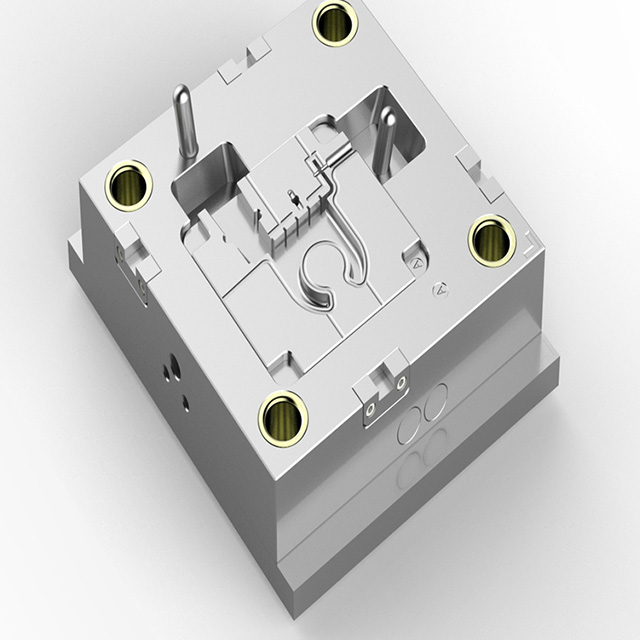

2. Main thechnology: Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc.

3. Producing Process: Audit drawings , mold flow analysis, design validation , Custom Materials, mold processing , core processing , electrode machining ,Runner system processing , parts processing and procurement, machining acceptance ,cavity surface treatment process , complex mode Die , The entire mold surface coating ,Mounting plate ,mold sample , sample test , sending samples

4. Product material: ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,TPR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS.

5. Equipment: CNC,EDM,Cutting off Machine,plastic machinery,etc

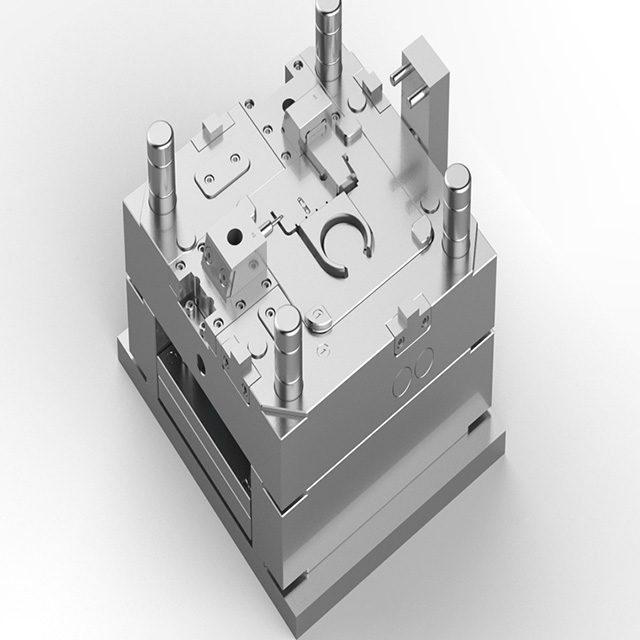

| We promise | All customer-centric, never for short-term profit, and sell long-term benefits |

| We produce | Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

| Pls provide | 2D, 3D, samples, or the size of the multi-angle pictures |

| Mould Time | 20-35 Days |

| Product time | 7-15 Days |

| Moud precision | +/-0.01mm |

| Mould life | 50-100 million shots |

| Mould cavity | One cavity, multi-cavity or same different products be made together |

| Mould material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Runner system | Hot runner and cold runner |

| Base material | P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

| Finish | Pitting the word, mirror finish, matte surface, striae |

| Standard | HASCO, DME or dependent upon |

| Software | CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

| Quality system | ISO9001:2008 |

| Establish time | 20~30 days |